The Crucial Connection: Matching the Right Plug with Your Welding Machine

|

Before we embark on our journey into the world of welding insights, ensure you've downloaded our one-page Infographic – your essential guide to selecting the perfect plug for your single-phase machine. |

|

Download a one-page Infographic |

|

In the world of welding, precision matters, and often, it's the small details that can make or break your welding experience. Consider, for instance, the plug that matches your welding machine's input cable and current. It may seem insignificant, but trust us, it's a big deal. Let’s unveil the hidden importance of selecting the right plug—a task that holds substantial weight. Whether you're a newcomer to welding or have a bit of experience under your belt, grasping the essence of this essential element can significantly enhance the safety and performance of your welding journey. |

Here's why matching the plug to your machine matters:

|

Adherence to Standards:Welding machines are designed to meet stringent standards, such as IEC 60974 or AS 60974. These standards extend beyond the machine, covering input cable and plug requirements, including specifying the plug size. Also, when purchasing, make sure your power source has this symbol (triangle E4824) meaning that it passed Regulatory Compliance Mark (RCM) to meet Australian and New Zealand regulations regarding electrical safety. This symbol indicates adherence to electrical safety and electromagnetic compatibility requirements, guaranteeing your safety. |

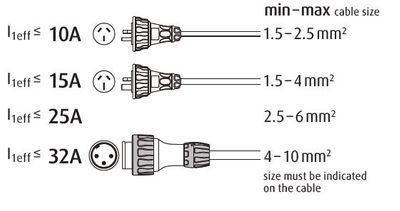

To Determine the Correct Plug: Navigating the EssentialsWhere to start? Well, the key player here is I1eff, which stands for the maximum rated effective supply current. You'll find this crucial number in your welding machine's operating manual, as it's the go-to reference for choosing the correct plug, input cable, and current settings. I1eff, determined according to the AS 60974-1 standard, considers both the machine's maximum current draw and its duty cycle, ensuring your welding machine operates safely and efficiently. |

|

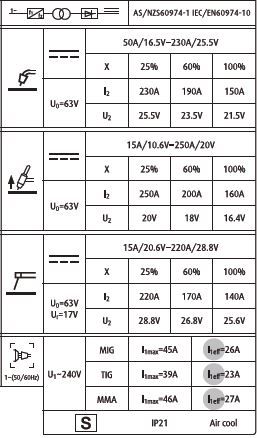

Check the Rating Plate:All welding machines complying with IEC 60974 or AS 60974 should sport a rating plate. Locate the I1eff value on this plate; it dictates the minimum plug size, input cable rating, and input circuit capacity needed for secure operation. |

|

Image: Example of Rating Plate |

| Consider this example: If your machine boasts an I1eff rating of 27A, a 32A plug is a must. Using a smaller 15A plug is inadequate, risking cable overheating and damage. |

Preventing Overheating:Operating a welding machine not only heats up the machine itself but also the input cable, plug, and mains power circuit. Ensuring the correct input circuit rating is vital to prevent overheating, tripping, and potential fire hazards. |

Do's and Don'ts:Do: Employ the correct input current, cable, and plug as specified by AS 60974-1 to ensure your safety and maximise your welding machine's performance. Always: Regularly inspect cables and plugs, and consult a qualified electrician for guidance, upgrades, or replacement of damaged components. Don't: Jeopardize your machine's integrity or invite tripping and fire hazards by using mismatched input current, cable, or plug. Never tamper with plugs or attempt to file down earth pins, as it may void your warranty. When purchasing the machine that requires plug more than 10A and your workspace lacks a suitable 240-volt 15-amp or 32-amp outlet, seek guidance from a qualified electrician. They can assess your building's wiring and suggest necessary upgrades to avert electrical fire risks. |

To wrap things up,Selecting the right plug that aligns with your welding machine's input cable and input current is far from a trivial choice—it's a critical aspect of safety and performance. By adhering to industry standards, verifying compliance marks, and seeking professional input when necessary, you can ensure the longevity and efficiency of your welding machine while safeguarding your workspace from potential hazards. And for your convenience, we've created a one-page infographic summarising the essential Do's and Don'ts when operating single-phase equipment. This handy reference will help you stay on the right track and keep your welding endeavours safe and efficient |